Ackumen™ Boiler Management

Simple, proactive low-pressure boiler system management

Boiler operators are constantly battling issues that plague their boiler system processes. Scaling and corrosion. Pretreatment and boiler inefficiencies. High fuel, chemical, and repair costs. Decreased equipment life. And unscheduled downtime. But did you know that you can predict and minimize those problems at every stage—from pretreatment to boiler to condensate?

What if you could be confident that you’re getting optimal:

Performance from your softener and insights into that performance

Regeneration from your softener tank, based on 24/7 monitoring

Results from your deaeration system

Monitoring of stack gas temperature

Treatment of condensate before it goes to the feedwater

With Ackumen Boiler Management, you can get insights into your boiler system from start to end.

Pretreatment

Water softener

Learn why your water softener is not working right and what you need to adjust it. That means you can address the potential for a scale problem before it makes it to the boiler. You also will reduce the likelihood of heat transfer inefficiency and avoidable stress on boiler equipment.

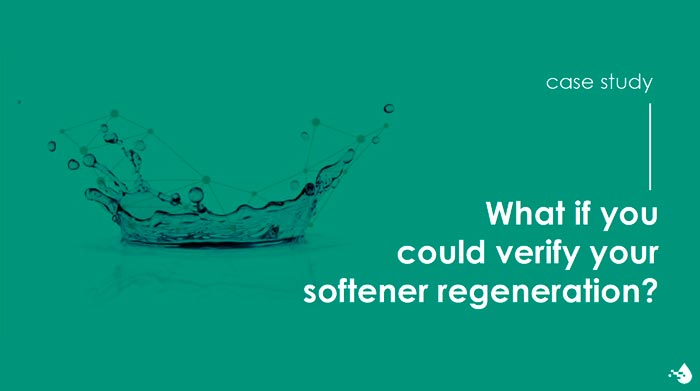

Softener regeneration

Get feedback on every softener regeneration to increase the likelihood your system is brining correctly. By ensuring regeneration is good, you’ll reduce the risk of scaling before it becomes an issue and potentially prevent unnecessary damage to your equipment.

Deaerator operation

Make sure your system is optimally and effectively removing residual oxygen. This unique service by Ackumen means you can reduce boiler corrosion, increase system efficiency and decrease the risk of system failure.

Boiler

Stack gas temperatures

Understand if you’re burning fuel efficiently. And if not, you can adjust and reduce the potential for scaling that leads to boiler inefficiencies. You’ll also get 24/7 monitoring which increases the certainty that the right chemistry is being used when boilers are idle or offline.

Enhanced boiler control

Control boiler water chemistry 24/7/365, including integrating blowdown control, using advanced technology, trained water treaters and state-of-the-art platform.

Condensate

Corrosion in the condensate

Reduce corrosion that results from condensate that’s too acidic. You’ll protect pipes and reduce energy inefficiencies and excessive feedwater usage.

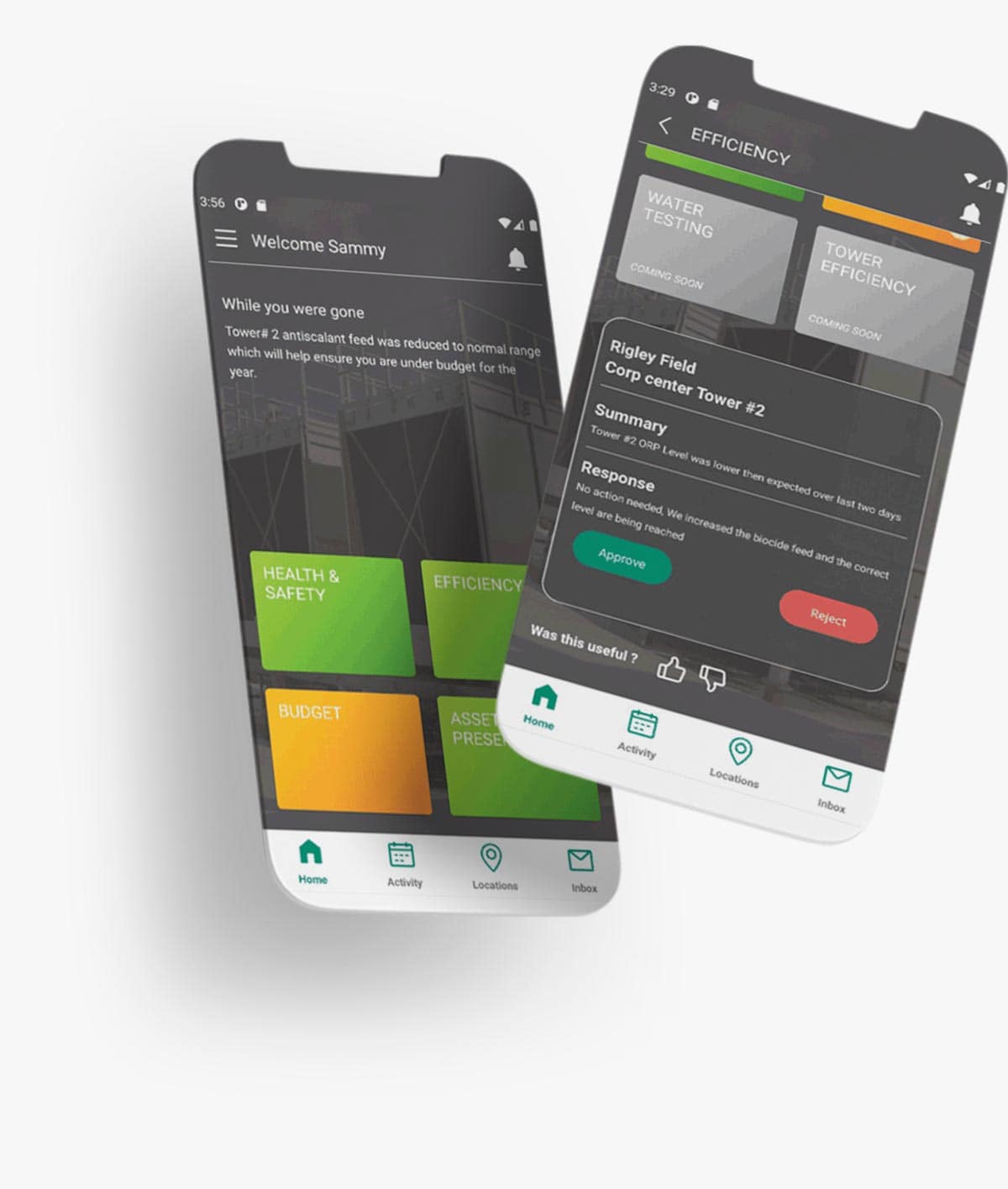

Get insights to help you succeed

The Ackumen digital solutions platform uses cloud-based data to deliver important insights right to your mobile device or desktop. You’ll get easy-to-read, actionable system graphics that show you how process indicators are behaving. You’ll also get alarms and notifications. And with just a glance, you’ll know whether an action is needed now or later.

Relax with support from the experts

The Insights Lab provides 24/7 monitoring by a team of data scientists and engineers. They deal with events as they happen. Assess every alarm. Eliminate false ones. And let you know if any action is recommended.

Manage chemistry better

SMART Inventory is our automatic inventory control system. It uses IoT sensors to monitor chemical supply in any container. You’ll get 24/7 inventory insights delivered directly to your mobile device. You’ll also get usage-based alerts, one-click ordering and more. Managing your chemistry has never been more efficient.

Have confidence in a safer work environment

When it comes to leak detection, we go the extra mile. Every panel on our skid contains a sensor. So if there’s a problem, such as an open valve, leaking chemicals, or a broken line, you’ll receive an alert that can help you prevent accidents.

Plus, through SMART Inventory and automatic reorders, you can minimize onsite chemical storage and still be confident you won’t run out of chemistry. With Ackumen, you also get alternative chemical delivery options that can help reduce the need to handle and store chemicals, and because no large containers are used, your employees are less at risk when it comes to switching out chemicals.

Ackumen Boiler Management can help make you the hero.

You’ll increase process efficiencies from start to end, protect equipment, cut costs and create a safer working environment

Case Studies

Ackumen™ Boiler Management, combined with the Insights Lab and advanced pretreatment monitoring, identified unknown operational inefficiencies at a small chemical manufacturer.

A microbrewery was able to increase their boiler efficiency and reduce the amount of time operators spent on manual blowdowns with Ackumen™ Boiler Management.

An unknown pump failure detected by Ackumen Boiler Management and assessed by the Insights Lab enabled a chemical manufacturer to optimize the boiler system and save water and energy.

Transparency provided by Ackumen Boiler Management enabled a chemical manufacturer to optimize surface blowdown and boiler chemistry.

A microbrewery was able to address brine draw issues and hard water excursions by adding pretreatment monitoring by Ackumen and the Insights Lab.